Differences between Double Helical Gear and Herringbone Gear. YouTube

Spur gear. Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with teeth projecting radially. Viewing the gear at 90 degrees from the shaft length (side on) the tooth faces are straight and aligned parallel to the axis of rotation. Looking down the length of the shaft, a tooth's cross section is.

Straight Cut Gears vs Helical What Are the Differences? Ran When Parked Car, Vehicle

Pros. A spur gear design is simpler to construct via hobbing. A straight cut system is less complex, which reduces manufacturing costs. Easier to assemble, owing to a simpler design. Straight cut gears improve efficiency by reducing drivetrain losses. Ergo, more usable power. Suitable for high rpm applications.

Buy Banshee STRAIGHT CUT 2.86 primary gears KIT online Panthera Motors

A straight cut gear can only achieve practical contact ratios of 1.2-1.9. Above 1.9 the tooth cross-section gets spindly and the strength is compromised. Below 1.2 gets too close to 1.0, which is dangerously close to the point of flirting with gear failure as the gear teeth load and- unload. Helical gears can achieve contact ratios of 2.2 to.

The Advantages And Disadvantages Of Straight Cut Gears CAR FROM JAPAN

Another benefit of helical gearmotors is their high efficiency. The angled teeth on the helical gears create a larger contact area than straight-cut gears, which helps reduce friction and energy loss. This makes helical gearmotors an energy-efficient choice for applications that require high torque and speed.

The Advantages And Disadvantages Of Straight Cut Gears CAR FROM JAPAN

1. Advantages of Straight-Cut Gears. Straight cut gears are known for producing no axial load like helical gears. As there is no axial load, there is no restriction applied on the torque. Hence, the straight cut gears are used in racing cars as torque is an aspect that is much needed in racing. The elimination of thrust force in straight cut.

Straight Cut Gears Standard Ratio w/ Starter Gear Redline Racing

A straight cut gearbox is a type of gearbox with gears that feature straight, parallel teeth. The gears are fixed on parallel axes, and the teeth mesh together in a way that all the load is distributed evenly across the entire gear width. This unique arrangement results in high power transmission, minimal gear noise, and improved efficiency.

Straight Cut Gear Peridot

The straight-cut gear teeth provide complete contact along each tooth's mating surface at all times, providing added strength over helical gears, and their straight profile also means that there's.

GT HD Gears 4th Gear Straight Cut 0.75 Vantopia

Straight Cut Gear Pros. Straight cut gears put no restriction on torque. That is because straight cut gears do not produce any axial load, like a spiral or helical gear would. For years, straight cut gears have been the standard in the world of racing, particularly Formula One. Race car drivers need to use a lot of torque, and the added thrust.

Useful Type of Gear Cutting Tools with KeyPoints

For helical gears, the benefits compared to straight cut gears are as follows: Lower Noise: By nature, helical gears can produce as much as 12 Db (A) less noise than similar size straight cut gears. For passenger car use or for a system used in your home like a washing machine, quiet operation is a great advantage.

Gear, 1st motion, 24 teeth, straight cut

Straight cut gears work by utilizing teeth that are cut straight on the gear faces to transfer power from one gear to another. As the teeth mesh together, the power is transmitted seamlessly through the gear train.. What Are The Benefits Of Straight Cut Gears? Straight cut gears can handle more power, reduce rotational mass, and provide.

Austin Healey Straight Cut Gear Set Tulip BJ8

6684. Straight-cut gears (spur gears) are the simplest type of toothing. In a spur gear, up to 3 teeth are in mesh at the same time. If the teeth of a toothed gearwheel run in a straight line, i.e. in the direction of the rotation axis, it is referred to as a spur gear or a straight-cut gear. Such a toothing can be produced very cost.

Straight, Gear Ratio 1.5, Bevel Gear 793DH8SUB23020 Grainger

Straight-cut gears are also much easier to assemble and produce less-catastrophic failures when they do go wrong due to their simple structure. Heavy-duty transmission casings and shafts have to be used with helical gears for the transmission to cope with the additional axial load, therefore straight-cut gears save heaps of weight which is.

Gear cutting (gear manufacturing) tecscience

And again, as someone else mentioned, straight cut gear sets don't have any side load issues. So durability is gained there also. Another big benefit of straight cut gears is significantly reduced transmission losses. Depending on car/box, the losses are reduced by a further 5% or more. Quite significant.

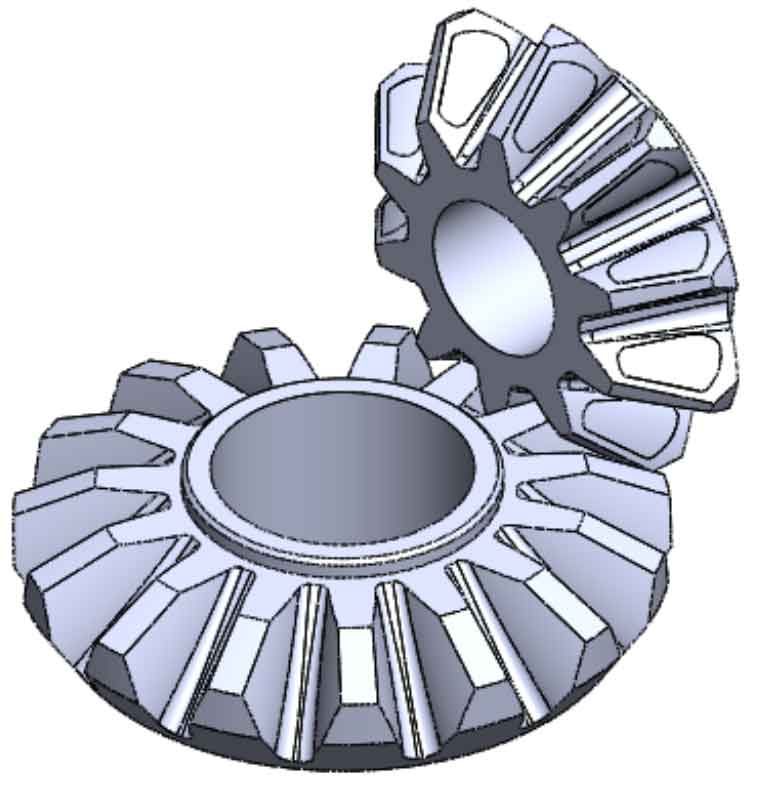

Rotary of straight bevel gear ZHY Gear

One of the most notable cons of straight cut gears is their higher noise level. The noise produced by straight cut gears is a loud "whining" that increases with RPM and is considered very unpleasant for automobile owners of today. Pros of Straight Cut Gears. For straight cut gears, the benefits compared to helical gears are as follows:

Straight cut gears explained as well as the Dog Box YouTube

"What Is A Straight Cut Gear?Watch more videos for more knowledgeStraight Cut Gears - YouTube https://www.youtube.com/watch/dmJH84FnQa8HELICAL VS. STRAIGHT C.

PPG 5MT Subaru Straight Cut Synchro Gears

Straight-cut gears come with a handful of advantages: they don't produce an axial load, don't generate much heat, and are easy to assemble. Some of the disadvantages of straight-cut gears include how they produce a lot of noise and vibration, can't carry heavy loads, and aren't suitable for city cars..

.